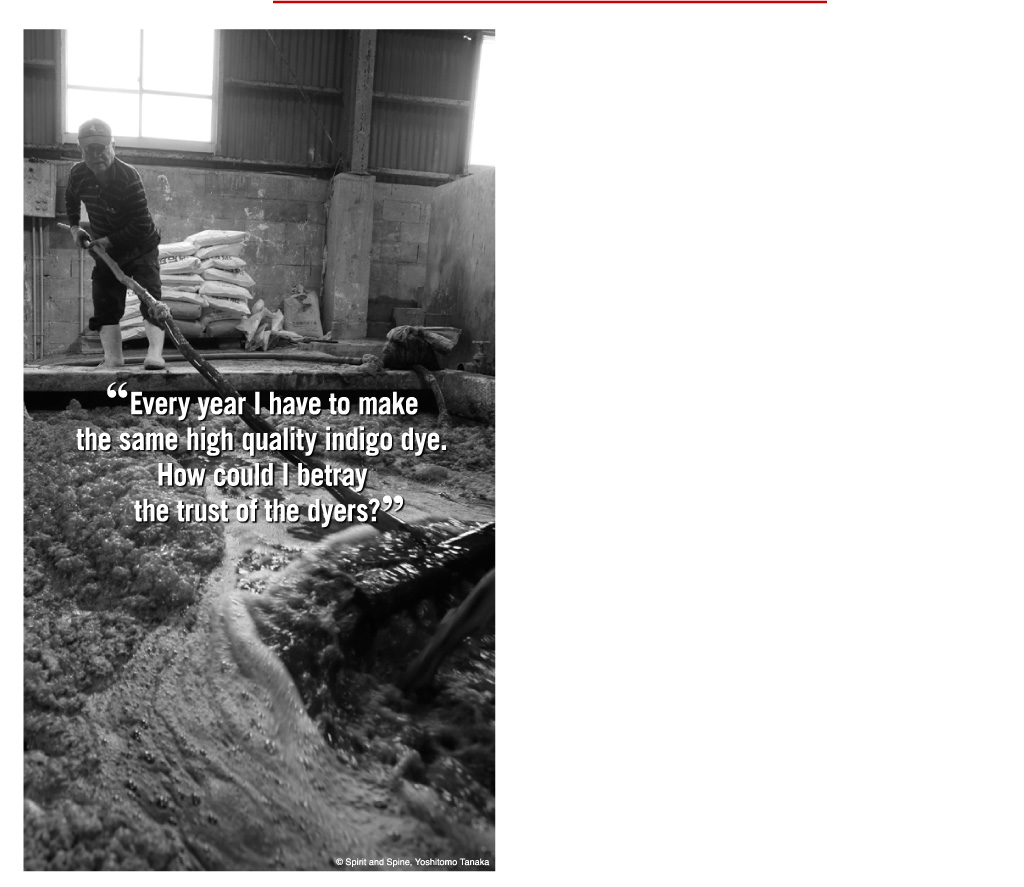

In the rainy season in Okinawa, a fully loaded small truck transports indigo leaves from the mountains into the factory. The rain is essential for making indigo dye. Amongst the stench and stifling humidity, tons of leaves are soaked in an enormous water tank. Several days later, the leaves will have liquefied and fermented producing a black muddy liquid that is poured into a vat below. It proceeds by adding and stirring in lime. In an instant that lasts less than a second, it changes to a red color. Ascertaining and not missing that moment is the most crucial part of indigo dye production. Like magic, it rapidly changes from grey to light blue, and then to a vivid ultramarine blue. The liquid on the top is skimmed off, the mixture is left to settle, and the mud indigo dye will be shipped out next year.

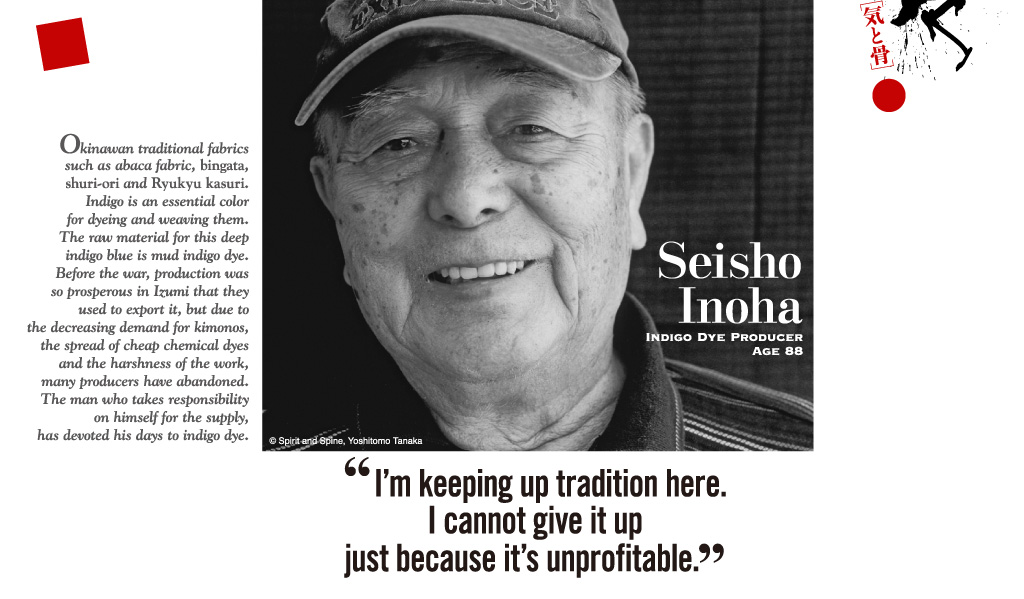

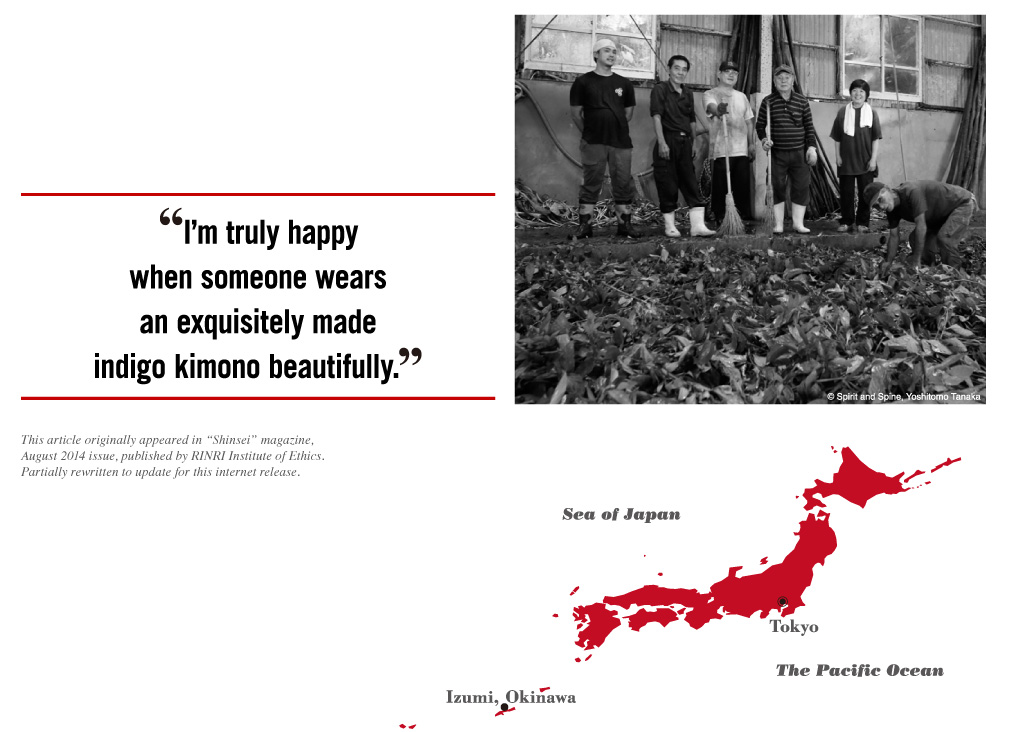

The Inoha family had samurai ancestors who served in Shuri, the political capital of the Ryukyu Kingdom. With the Meiji Restoration they lost their social status, and started cultivating indigo and producing indigo dye in Izumi. From a young age, he followed in his father’s footsteps and he’s the fourth generation of his family in this business. The number of manufacturers is decreasing rapidly because of the dislike of the hard labor and the difficulties involved in cultivation, like repeated planting not being possible and crops being dependent on the weather. Once, he too decided to quit the business due to the heavy pressure he felt for being responsible for the supply. Many craftspeople, who heard about this, negotiated with the government and won some aid for him, which made him abandon his decision to quit.

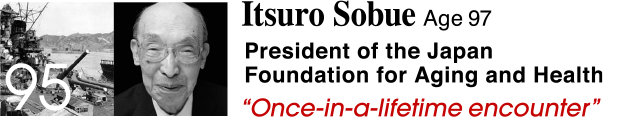

During the Battle of Okinawa, there was a continual flight of inhabitants from the south to the north of the main island. He and his family also fled and hid in the mountains. Even after the occupation, they continued to hide from the US armed forces. Okinawa had been transformed into a battleground and even after the end of war the citizen death toll continued to mount.

The production of indigo dye really isn’t suited to making a profit, but he continues to maintain and preserve the Ryukyu traditional deep indigo color, due to his sense of duty and with the help of his family and those people who support him.